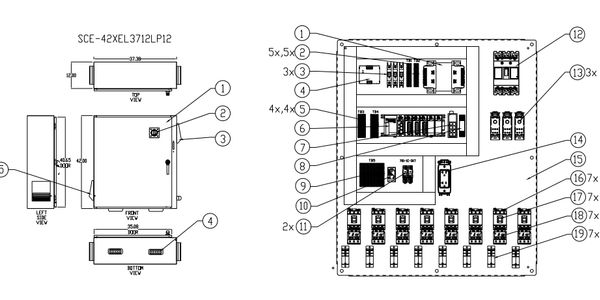

PANEL ASSEMBLY

CONTROL PANEL DESIGN

We take great care into designing a control panel. Every component is individually sized and selected to maximize system robustness. All calculations are double checked before parts are ordered.

We encourage our customers to inform us if they would prefer a different brand or component in their panels. We fully understand that having the same parts as what's in the rest of the facility greatly reduces inventory costs.

In the pass, we have had customer specifications for Allen Bradley, OMRON, Siemens, Koyo and various other products.

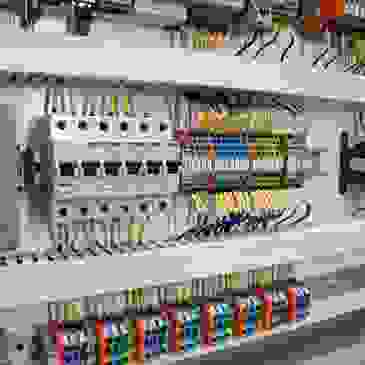

PANEL ASSEMBLY & WIRING

Assembly and wiring is done at our panel shop. Assembly and wiring begins only after our customers feel confident that Absolute Automation is providing a solution that meets the specification.

All holes are drilled and tapped to the correct thread size. All wires are crimped to ensure a tight fit into the termination points.

PANEL TESTING

Every panel undergoes a thorough QC check and then powered ON. Once powered ON, all components that can be tested will be cycled to make sure it's functioning properly.

A copy of the electrical drawings (as-is) at time of testing is shipped with the control panel.

ELECTRICAL PANEL

ELECTRICAL PANEL

ELECTRICAL PANEL

Whether our customer needs a panel built-to-print or a new system, we are capable to delivery completed electrical control panels.

PNEUMATIC PANEL

ELECTRICAL PANEL

ELECTRICAL PANEL

Pneumatic Assembly panels may be sized and designed to customer specification or could be build-to-print.

WIRE ASSEMBLY

ELECTRICAL PANEL

WIRE ASSEMBLY

Absolute Automation provide services for wire harness assembling to save time due to labor shortages.

Copyright © 2014 Absolute Automation - All Rights Reserved.